Important Installation Requirements for CPV Tube Fittings

The O-ring is the sealing component in CPV tube fittings. To seal, this O-ring must be completely surrounded by metal. Therefore, the FLAT FACES on the body and tailpiece MUST BE IN COMPLETE CONTACT upon installation.

If there is any space between the fitting faces-due to misalignment or insufficient tightening-the O-ring may blow out or extrude through the gap. 0-ring failure is due to improper installation and will cause leakage.

Proper installation will assure a leaktight connection. At our valve manufacturing company we want to help you and your CPV tube fittings do the best job possible. If there are any questions about installation procedures, please contact CPV.

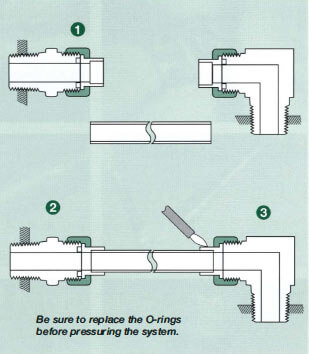

Fig. A. Full, face-to-face contact is essential. This encapsulates the O-ring, and assures a leak-proof seal.

Fig. B. No misalignment can be tolerated. The fitting is not a “tube straightener.”

Fig. C. It’s not a “tube stretcher.” You can’t successfully compensate for a “too short” tube by excessively torquing the fitting nut.

Suggested Installation Procedure

- Install threaded end of each CPV tube fitting and cut tube to the required length, including allowance for fitting sockets. Remove O-ring from each fitting to prevent heat damage. Clean tube and fitting socket-both must be free from grease, rust, etc. For brazing, apply flux to tube and socket, and insert preformed sil-braze ring, if used.

- Place tailpiece on each end of tube. Reassemble fittings and tighten nuts to bring fittings completely together. Check to make sure that tube and fittings are properly aligned.

- “Heat-seal” the fitting to the tube: BRAZING. Melt a pre-inserted sil-braze ring in the tube socket or face feed the sil-braze alloy until a full fillet is formed at the juncture of the tube and fittings. WELDING. Tack weld tube to fittings, if possible, and remove to complete welding operations. When installing any CPV tube fitting, proper tube alignment and face-to-face contact are essential (see Fig. A) – and are achieved easily with normal care. Contact our valve manufacturing company with any questions!